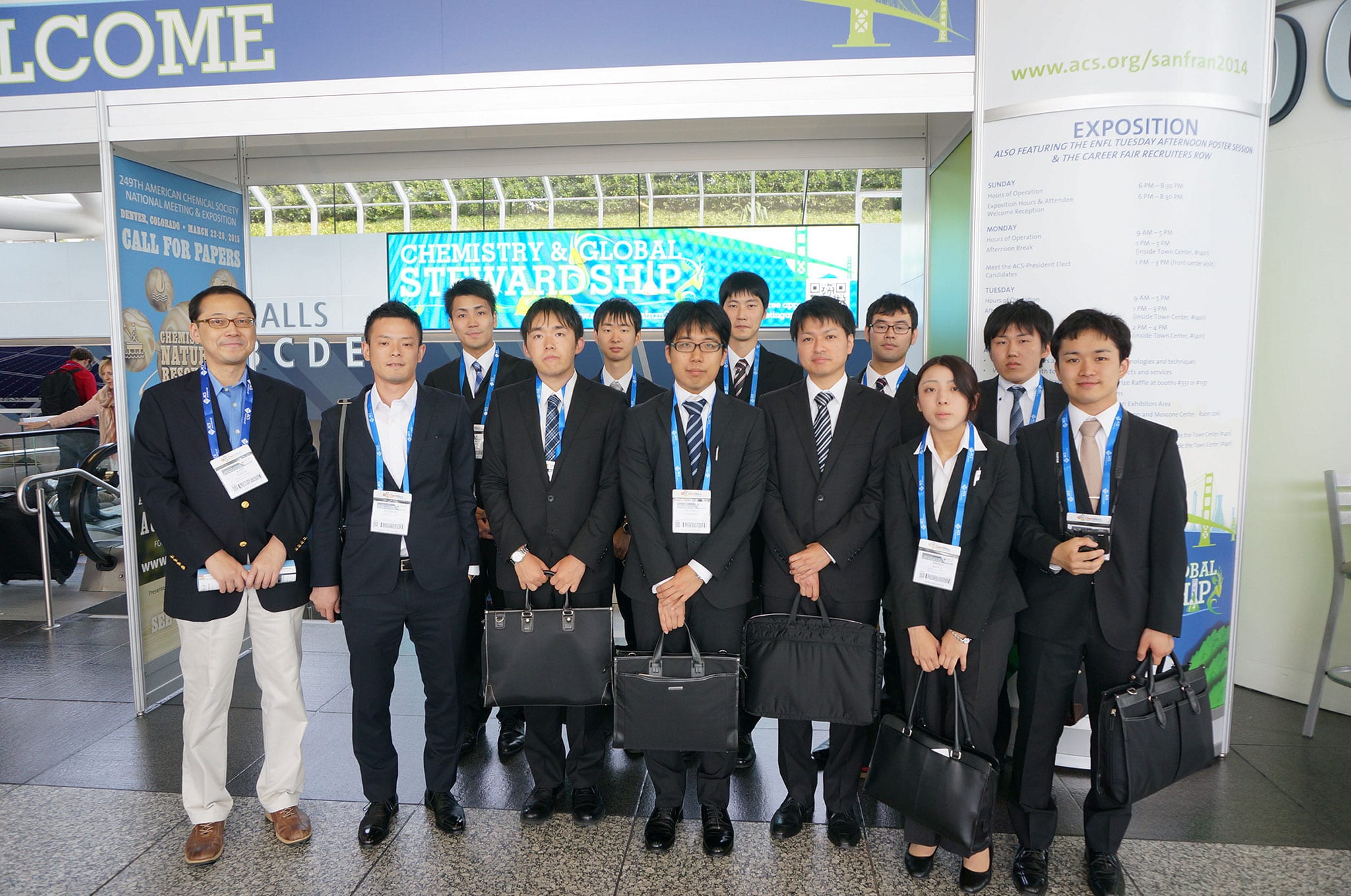

Professor Kazukiyo Nagai

Professor Kazukiyo Nagai Plastic in the wonderland: the world of membranes

We develop new materials and concepts for next generation polymeric functional membranes, which include (1) gas separation membranes for carbon dioxide capture, hydrogen purification, petroleum gas separation and natural gas processing, (2) gas permeation membranes for contact lenses and artificial lungs, and (3) high barrier membranes for organic electroluminescence, solar cells, flexible displays, and packaging applications.

Membranes for CO2 separation and H2 purification

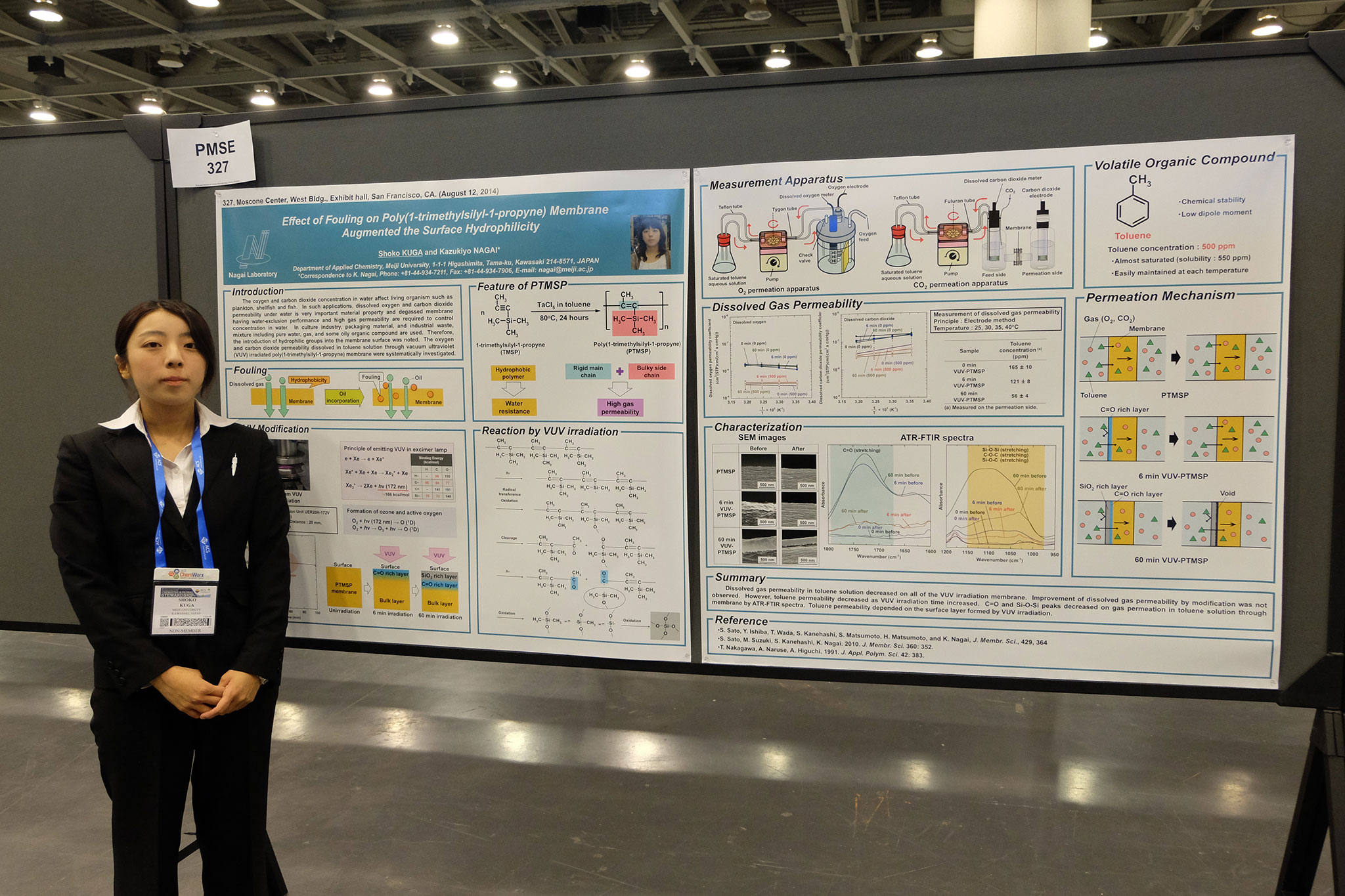

Membrane is an interphase between two adjacent phases acting as a selective barrier, regulating the transport of substances between the two compartments. It is employed for specific functions including separation of gases and liquids, ions, or biological matters. Membrane separation technology enjoys various advantages over conventional methodologies such as isothermal operation at low temperatures, no requirement for additives, low energy consumption and ease of integration into other separation or reaction processes. To date, this technique has gained multidimensional significance as in air separation, nitrogen purification, natural gas separation, flue gas purification, dehydration, volatile organic compounds (VOC) recovery etc. In particular, many countries focus on both the production of hydrogen as a clean energy source and removal of carbon dioxide (CO2) to prevent global warming. High-pressure CO2 can plasticize glassy polymer membranes.

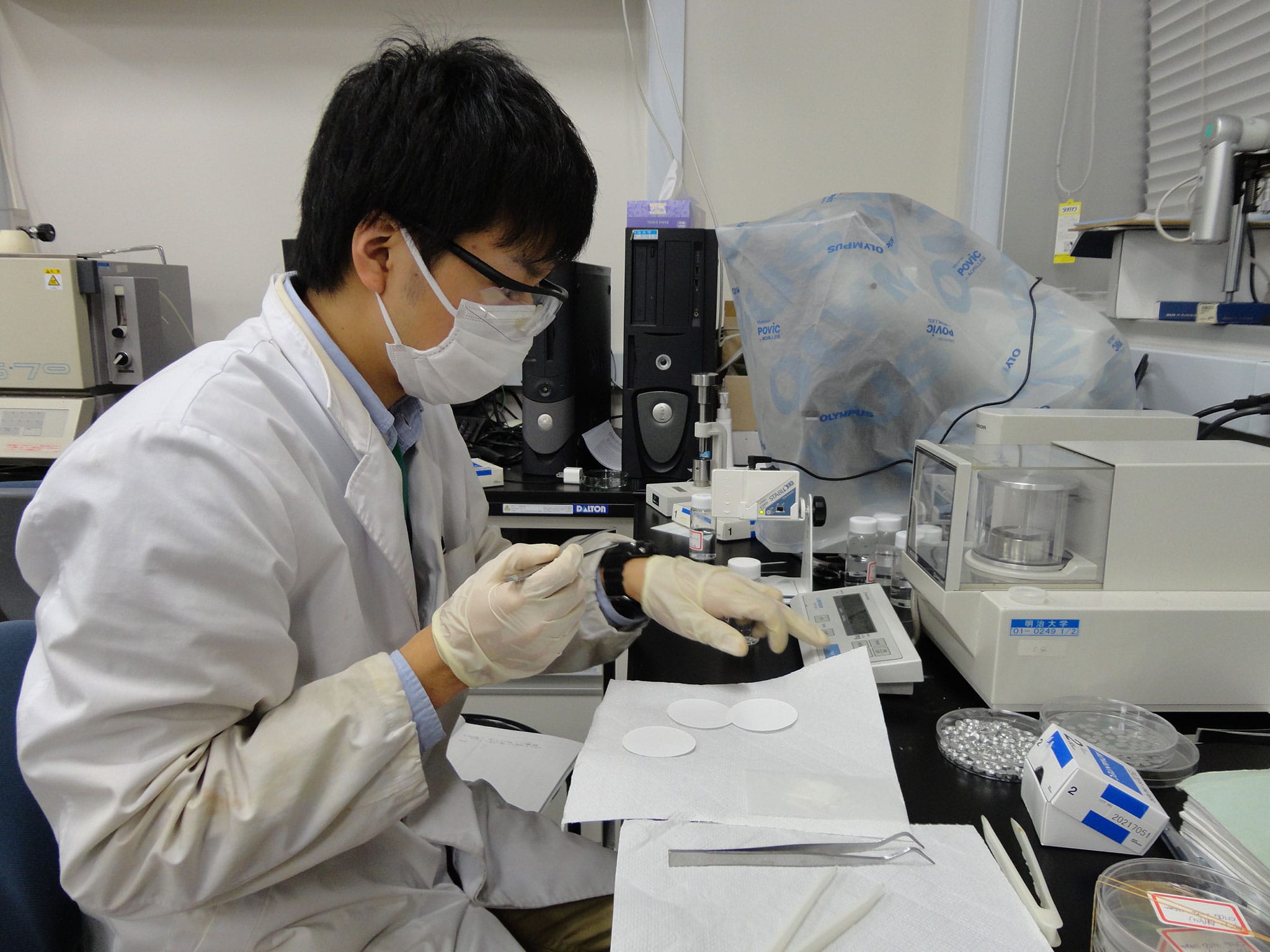

Membrane plasticization has a negative impact on gas separation involving natural gas purification (CO2/CH4 separation), the removal of CO2 from power plant emissions (CO2/air separation), and hydrogen purification (CO2/H2 separation) for use in fuel cells and oil refining. As a matter of fact, properties of a membrane strongly depend upon the chemical structure and microstructure of the polymer. Therefore, the synthesis of novel polymers with well-defined structure as designed membrane materials, will not only contribute to the development of new membrane materials but will lead to a significant advancement in the science and technology of membranes as well (see Figure 1). Our aim is the development of polymeric separation membranes for greenhouse gas, especially CO2, recovery against global warming.

Figure 1. Polymer membranes made from rice.

Figure 1. Polymer membranes made from rice.

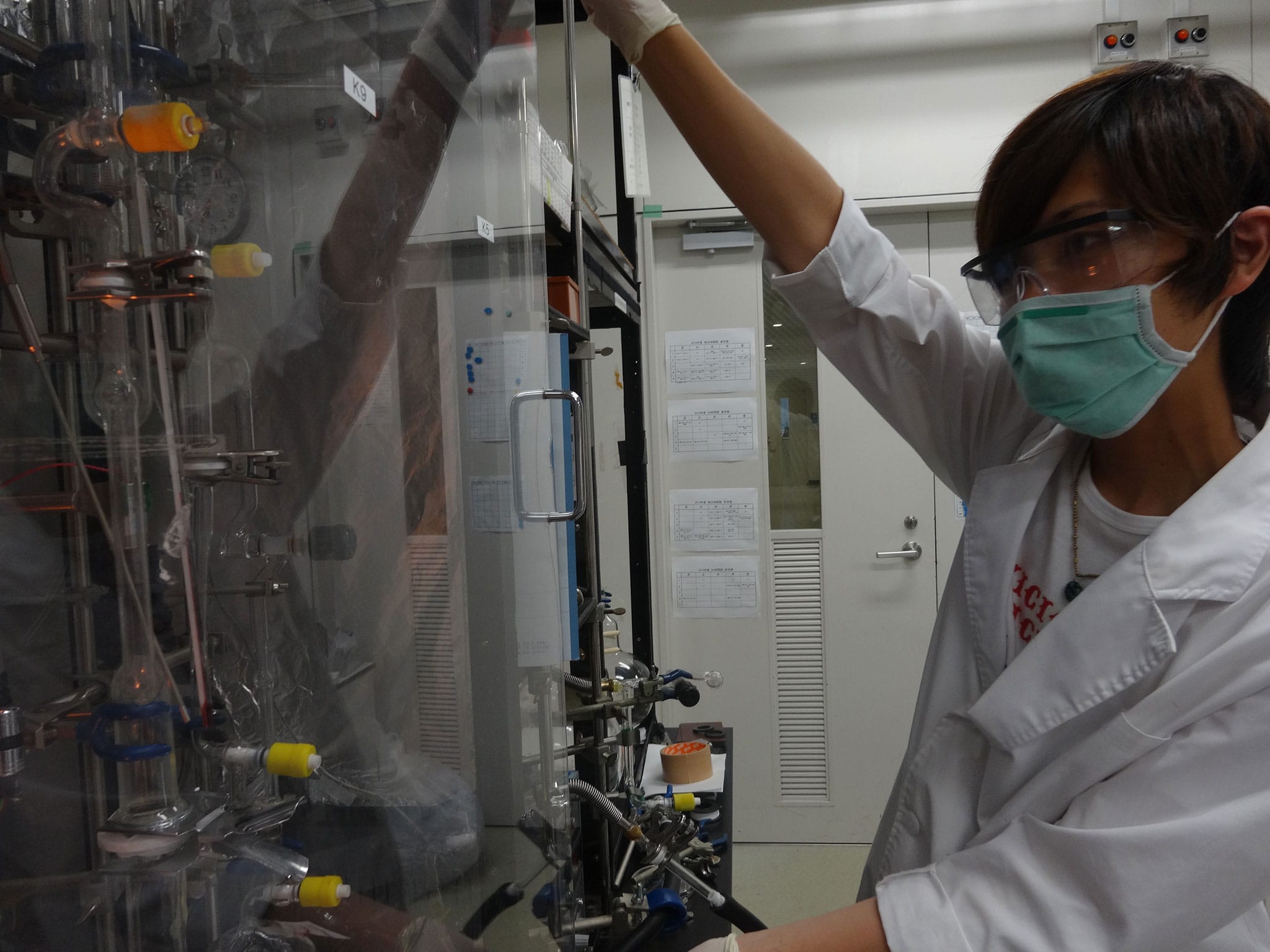

Membranes for printed and flexible electronics devices

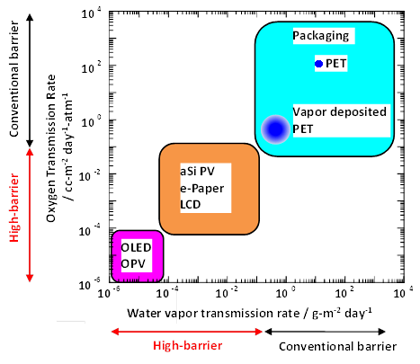

A plastic substrate can provide flexibility to organic light-emitting diodes (LEDs), solar cells, batteries, and displays. However, compared with a glass substrate, a plastic substrate has poor water vapor and oxygen barrier properties. For example, in using organic LEDs, a water vapor transmission rate (WVTR) of less than 10-6 g m-2 day-1 is required for the substrate (see Figure 2).

This rate is much lower than the analytical limit of current commercial technologies. It is, therefore, very difficult to determine permeability through higher-barrier films such as multilayered organic-inorganic flexible films with WVTR of less than 10-4 g m-2 day-1. So far, various higher barrier analysis methods have been proposed; it is still a developing technology. Our aim is the development of higher-barrier films and measurement methods of their barrier properties.

Figure 2. Requirement of water vapor and oxygen barrier properties.

Figure 2. Requirement of water vapor and oxygen barrier properties.

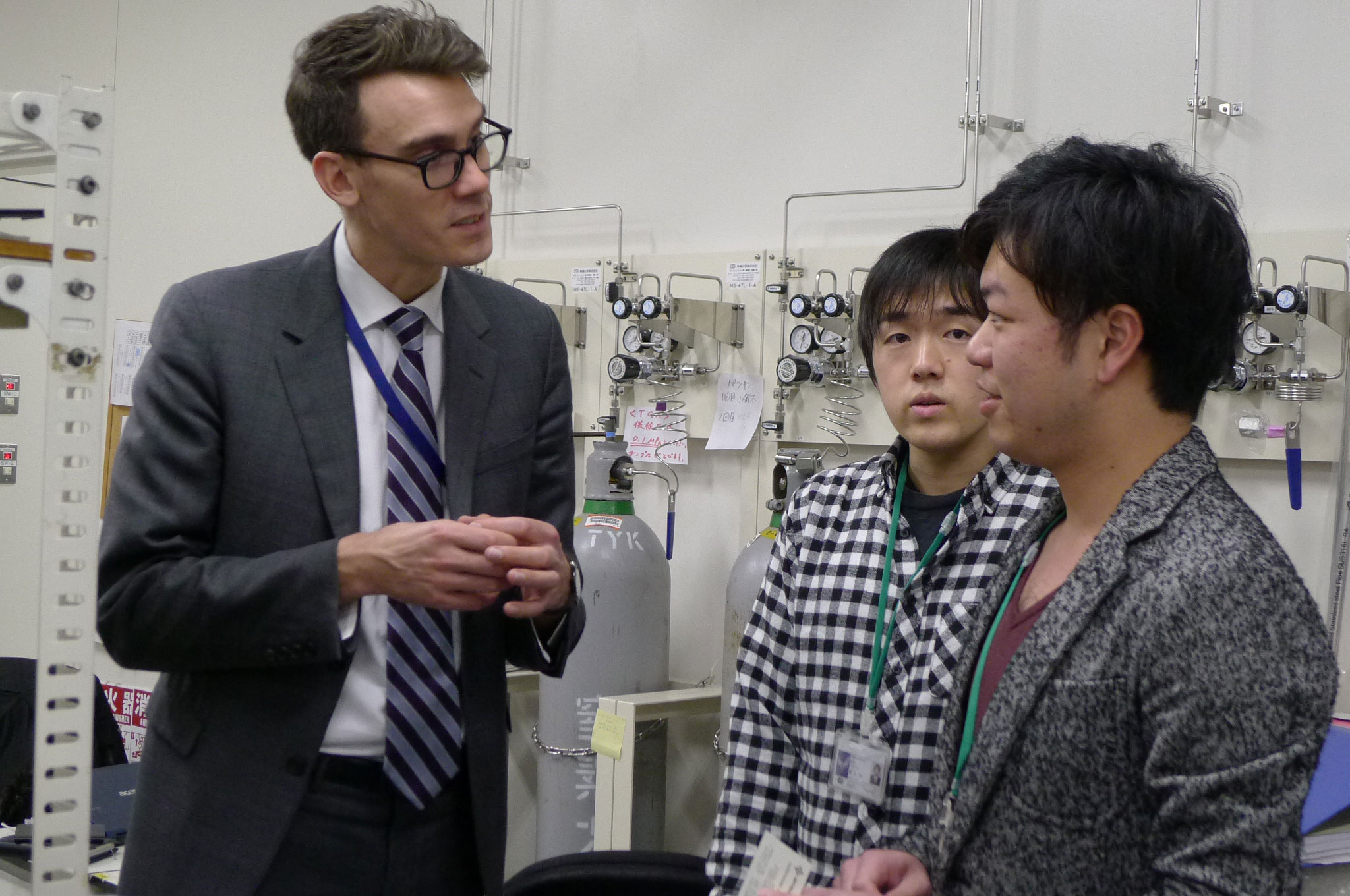

The Earth-friendly materials forward to reduce plastic garbage

The establishment of a sustainable society has been promoted based on the Sustainable Development Goals (SDGs), proposed in The 2030 Agenda for Sustainable Development that came into force by the United Nation on January first, 2016. In Japan, “Containers and Packaging Recycling Law” was fully enforced. And the 3R’s (Reduce, Reuse, Recycle) has transformed society from a mass consumption society into a recycling society. It has become rooted in daily life, and the effect has been shown to reduce waste.

On the other hand, it is becoming clearer each day that plastic waste such as disposable plastic containers and packages that flow out to the oceans have an adverse effect not only on the landscape but also on marine life. In particular, we also have found new international issues such as adverse effects on marine ecosystems due to misinformation of miniaturized plastic marine waste (micro plastic). Discussions of the impact of micro plastics caused by frictional wear from land tires, fibers and paints have also started on land.

As countermeasures against environmental problems and depletion of resources become more severe on an international scale - especially for packaging materials which are distributed in large quantities by multiple routes - we enter an era where resource recycling must be considered throughout the entire lifecycle. This should include logistics such as collection routes. Furthermore, there is a movement to reduce food loss by moving on from current method such as printing bar codes on packaging, to introducing IoT (Internet of Things) and AI (Artificial Intelligence) which is a far more efficient approach. In addition, in regards to improving the functionality of containers and packages, transparent plastic films for OEL (organic electroluminescent) in the field of electronics are currently unavailable for packaging materials such as foods and medicines because the prices are extraordinary high. These plastic films are expected to develop for applications that require "transparent and contents are visible" in the future.

Regarding materials, the use of biomass plastic is becoming increasingly appealing to consumers, poly(ethylene) (PE) and poly(ethyleneterephthalate) (PET) synthesized from plant-derived materials are being spread as Bio PE and Bio PET. Demand for biomass plastics is expected to grow worldwide due to their impact various parts of the global environment such as the reduction of greenhouse gas emissions and the impact on recycling.

Our goal is to create earth-friendly materials to reduce plastic waste.

Contact details

Kazukiyo Nagai

Department of Applied Chemistry, Meiji University

1-1-1 Higashi-mita, Tama-ku, Kawasaki 214-8571, Japan

E-mail: nagai@meiji.ac.jp