Plastic and Sound Material-Cycle Society

1.Shift to Sound Material-Cycle Society

Stable supply of food, water, and energy is necessary for human lives. A supply problem arises because Japan has confined land and poor natural resources. Moreover, trash must be processed properly after consumption. We always need to keep the environment clean when we obtain resources.

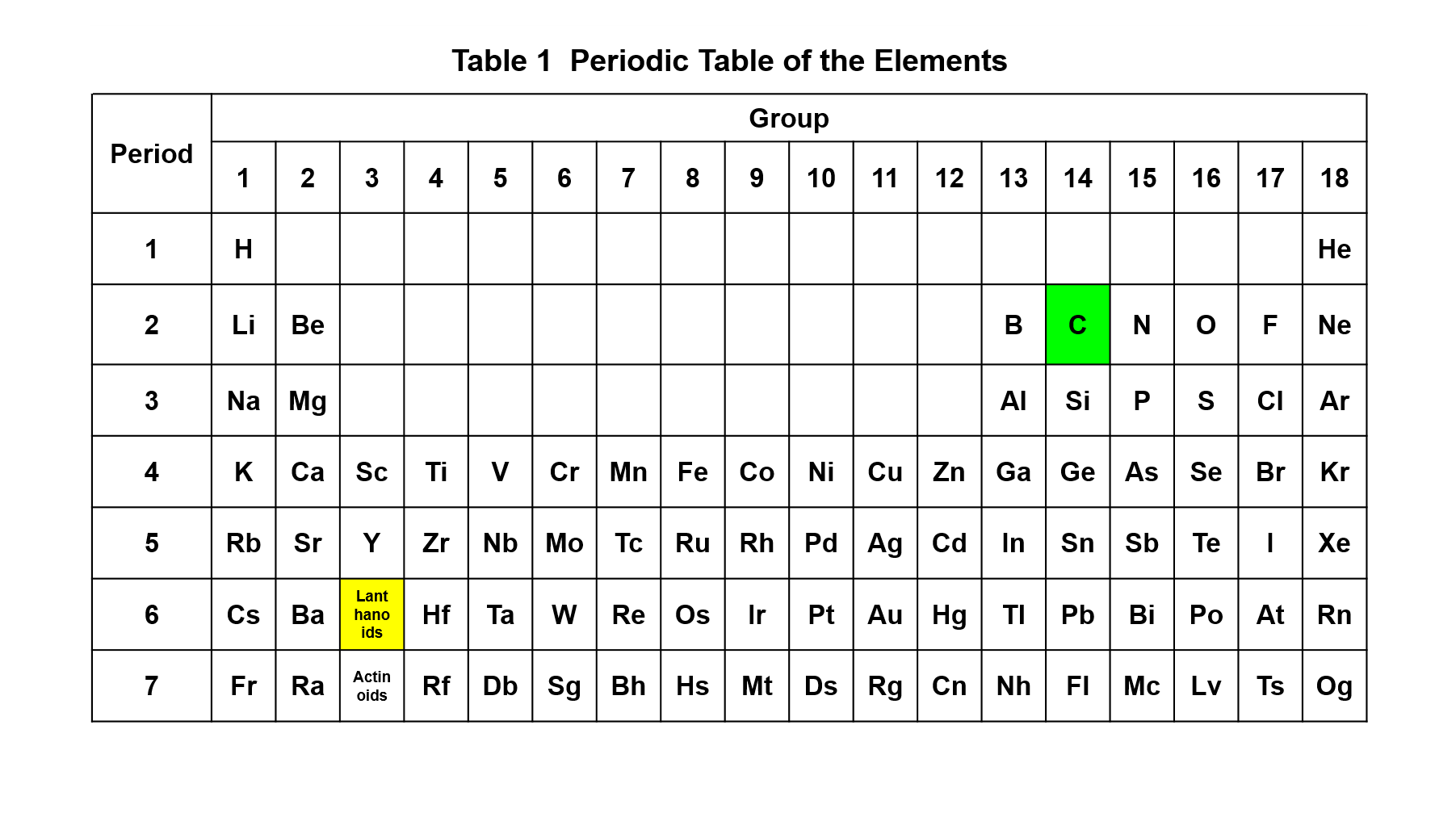

Science developed technology, which makes our life easier, but where the elements of whatever we produce such as electrics, vehicles, trains, air planes, houses, buildings, and clothes come from must be considered. The elements on earth are shown in the periodic table (Table 1). Plastics and all the organic chemical products including medicines are organic compounds, which have a carbon atom as their bone structure. Today, most organic compounds rely on fossil fuel, but it is a depletable resource that will remain for the next 50.6 years according to the Energy White Paper 2018. Obtaining a stable supply for rare earth elements such as lanthanoid, cerium, and neodymium that are necessary for smartphone, smart electrics, and electric vehicles became difficult lately.

The Ministry of the Environment promulgated The Basic Act for Establishing a Sound Material-Cycle Society in 2000. It defined Sound Material-Cycle Society as “a society in which the consumption of natural resources will be conserved and the environmental load will be reduced to the greatest extent possible, by preventing or reducing the generation of wastes, etc. from products, etc., by promoting proper cyclical use of products, etc. when these products, etc. have become circulative resources, and by ensuring proper disposal of circulative resources not put into cyclical use.” A reason for establishing this act is that landfill life in financial year (FY) 1996 was estimated to be 8.8 years for domestic waste and 3.1 years for industrial waste. Creating the Sound Material-Cycle Society became urgent to transcend the economical society of mass production, mass consumption, and mass discharge.

2.Reduce, reuse, and recycle

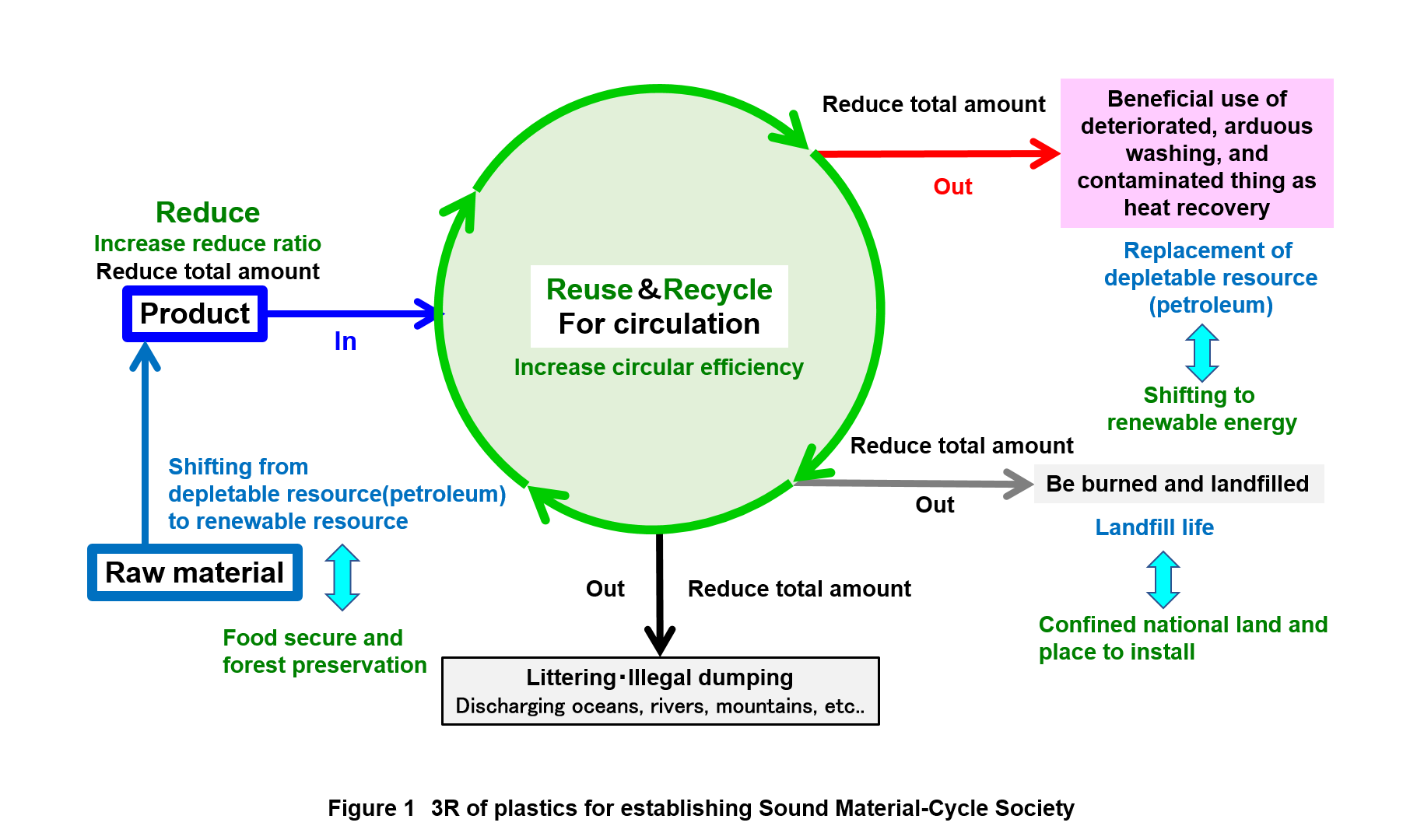

Establishing Sound Material-Cycle Society has two key points, namely, boosting reduce, reuse, and recycle (3R), and proper garbage processing, and they are supported by Law for Promotion of Effective Utilization of Resources and Waste Management Law, respectively. Figure 1 shows the conceptual diagram of 3R which aims for low-environmental-load Sound Material-Cycle Society using plastic as an example. In this diagram, reduce decreases the frequency of consumption in society, reuse and recycle, which include material recycle and chemical recycle, work for circulatory usage of things. Ideally, the circulatory cycle should continue forever, but deteriorated things, arduous washing things, and contaminated things are difficult to recycle in reality. According to An Introduction to Plastic Recycling 2018 published by Plastic Waste Management Institute, polyethylene, polypropylene, and polystyrene which are often used for packaging material, have the same heating value as Bunker A, liquefied petroleum gas, and city gas. Therefore, difficult things for recycling are used as replacement for depletable fossil resources and take heat recovery (energy recovery). This practice could help reduce petroleum consumption. The rest of the things which cannot even take heat recovery will be burned or landfilled.

We learned about three types of recycling in high school: material, chemical, and thermal. The term of heat recovery indicates thermal recycling, but we cannot reuse the heat because it is burned in reality. Therefore, it is excluded from the circulatory system in Figure 1. In industry field, it is discussed with the terms of energy or heat recovery instead of thermal recycling to distinguish it from material recycling and chemical recycling.

The Basic Act of Sound Material-Cycle Society set up the priority of processing waste as (1) reduce, (2) reuse, (3) material and chemical recycle, (4) energy recovery, and (5) burn or landfill. It requires proper management and overall evaluation by life cycle assessment (LCA) including low carbon dioxide discharging energy and efficient water consumption. LCA is the process that considers what material could consume fewer resources and make result in lesser damage to the environment. This idea is used in each level of the developing stage of product lifecycle and in quantitively evaluating the environmental load. Resource circulation requires recycling, but applying energy recovery for lesser carbon dioxide discharge is better in several cases. Therefore, we need to comprehensively evaluate the environmental factors and determine what is best for the earth.

Figure 1 shows a trade-off in blue and green letters. Plastic resources transition from depletable petroleum to plant as renewable resources, but problems of food security and forest preservation must be considered. In terms of energy recovery from plastics that difficult to recycle, whether we can keep stably activating facilities during the transition to renewable energy need to be discussed. In addition, we must stably recover and supply garbage to run facilities, and consider the balance between energy recovery ratio and economics. Burning and landfilling triggered the transition of the Sound Material-Cycle Society because of our limited landfill capacity, but Japan has confined national land and minimal room for new facilities.

Low-profit educational campaign is important for achieving zero waste in the environment, and littering or illegal dump is beside the question. Moreover, a penalty must be imposed. Under Basic Act for the Promotion of the Recycling-Oriented Society, Containers/Packaging Recycling Act, Home Appliance Recycling Act, Food Recycling Act, Construction Material Recycling Law, End-of-Life Vehicle Recycling Law, and Specified Kinds of Home Appliances Recycling Law were established in 2000, 2001, 2001, 2002, 2003, and 2013, respectively. These laws meant to address waste in the environment for a long time. However, no critical solution is available for them or even littering and illegal dump. Ocean waste, which is a global issue today, has poor scientific evidence. Therefore, statistical data must be collected to determine status.

3.Managed litter and not managed litter

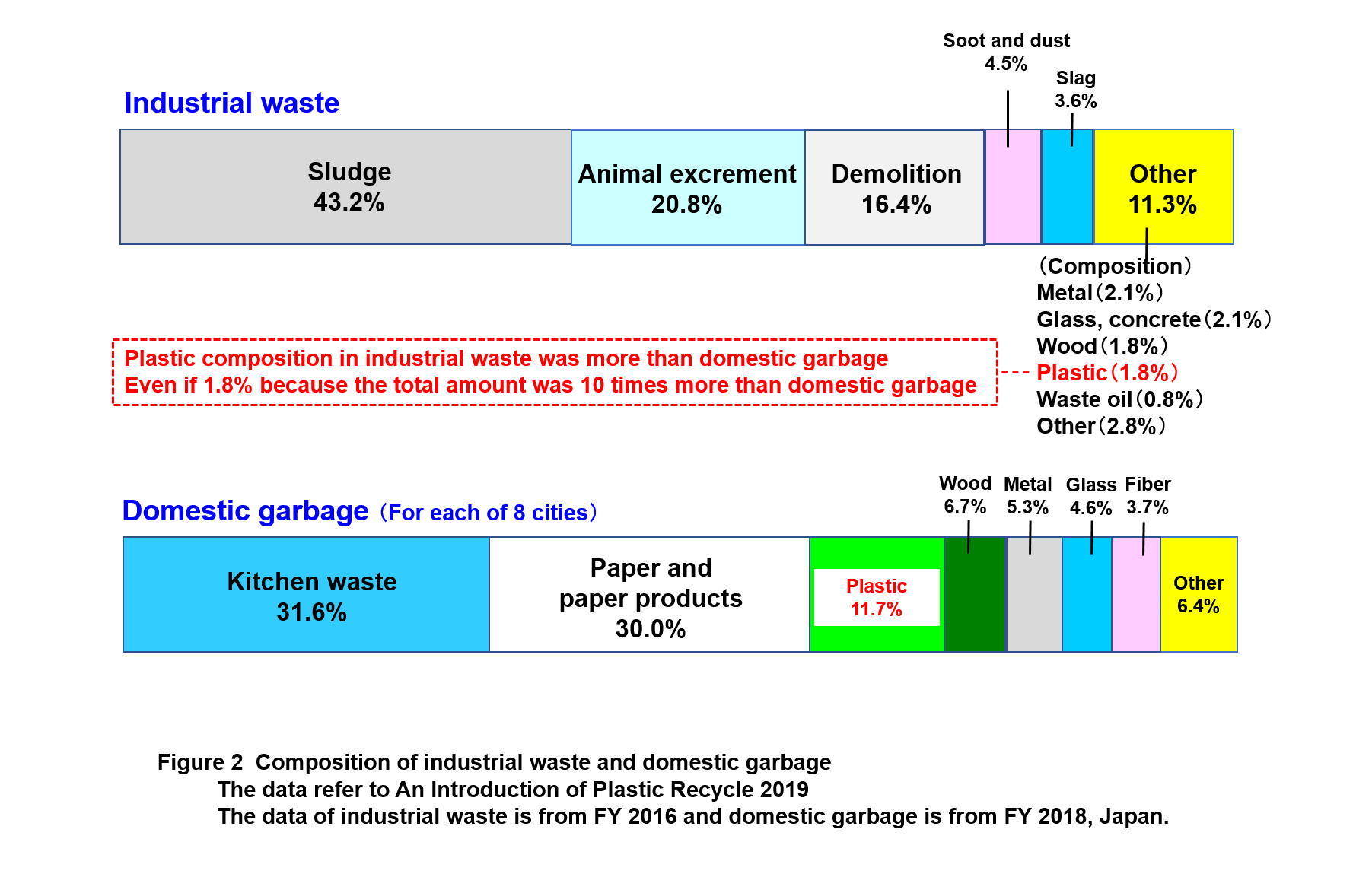

Creating the Sound Material-Cycle Society needs to manage the supply chain and make status or improvement from material flow made with statistical data. In this part, the status of plastic litter from statistical data will be reviewed. Details are available on the web site of Plastic Waste Management Institute (https://www.pwmi.or.jp/ei/index.htm). According to An Introduction to Plastic Recycling 2019, Japan produces slightly less than 400 million tons of industrial waste per year and about 40 thousand tons of domestic waste. The amount of industrial waste is ten times more than that of domestic waste. A breakdown of industrial waste reveals that 43.2% of the total is sludge, followed by animal excrement (20.8%), and demolition waste (16.4%). By contrast, waste plastics account for a very small (1.8%). Examining the composition of domestic garbage show that kitchen waste and paper account for 32% and 30%, respectively, followed by plastics at 12%. The percentage of plastic in industrial waste looks small, but the total amount of garbage is almost ten times; thus, it exceeds that of domestic waste. (Original article in Japanese used data from An Introduction to Plastic Recycling 2018.)

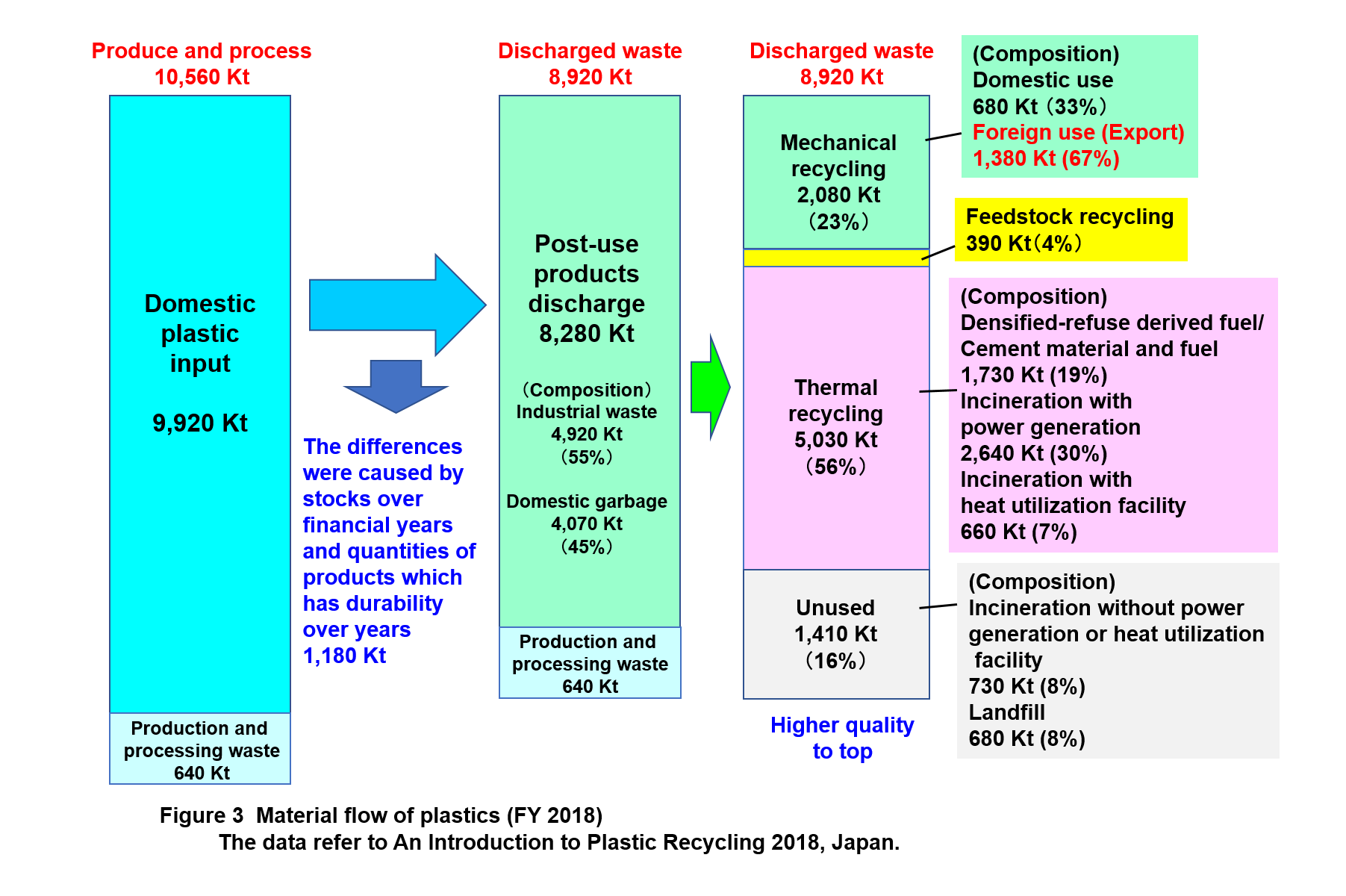

The material flow of plastic is shown in Figure 3. The amount of produce and process in FY 2018 was 10,560 thousand tons which was total amount of 9,920 thousand tons for domestic plastic input and 640 thousand tons for production and processing waste. Total amount of discharged plastic waste is 8,910 thousand tons, and the breakdown shows that industrial waste and domestic waste are 4,290 and 4,620 thousand tons, respectively. This number meets Figure 2. Production and processing waste discharge is applied as is. The difference between resin production and total plastic waste discharge is calculated as 176 thousand tons, but it is thought to be cause by stocks over a financial year and quantities of products, which have durability over years. In addition, amounts of discharged and processed waste are met. Where does scattered waste in the environment come from in this material flow? Focusing on marine waste, which is discussed worldwide, the amount of plastic waste discharged in the ocean was estimated to be 480 – 1,270 thousand tons per year by people living in 192 countries touching oceans in 2010 according to a report (J. R. Jambeck, R. Geyer, C. Wilcox, T. R. Siegler, M. Perryman, A. Andrady, R. Narayan, K. L. Law, Plastic waste inputs from land into the ocean, Science, 347, 768-771, DOI: 10.1126/science.1260352 [2015]). The top three countries are China, Indonesia, and Philippines and the amounts of discharged plastic waste were 132–353, 48–129, and 28–75 thousand tons per year, respectively. Japan ranked 30th with an estimated 2–6 thousand tons per year of plastic waste discharged. If the resin production would be set as 1,000 thousand tons per year, the percentage of plastic waste discharged into the ocean would be 0.2–0.6%. The ratio looks small, but it is not ignorable.

The material flow in Figure 3 shows that recovered waste appears managed based on statistical data. Therefore, some percentage of the amount of the gap between resin production and plastic waste is inferred to be discharged into not only oceans but also rivers, mountains, parks.

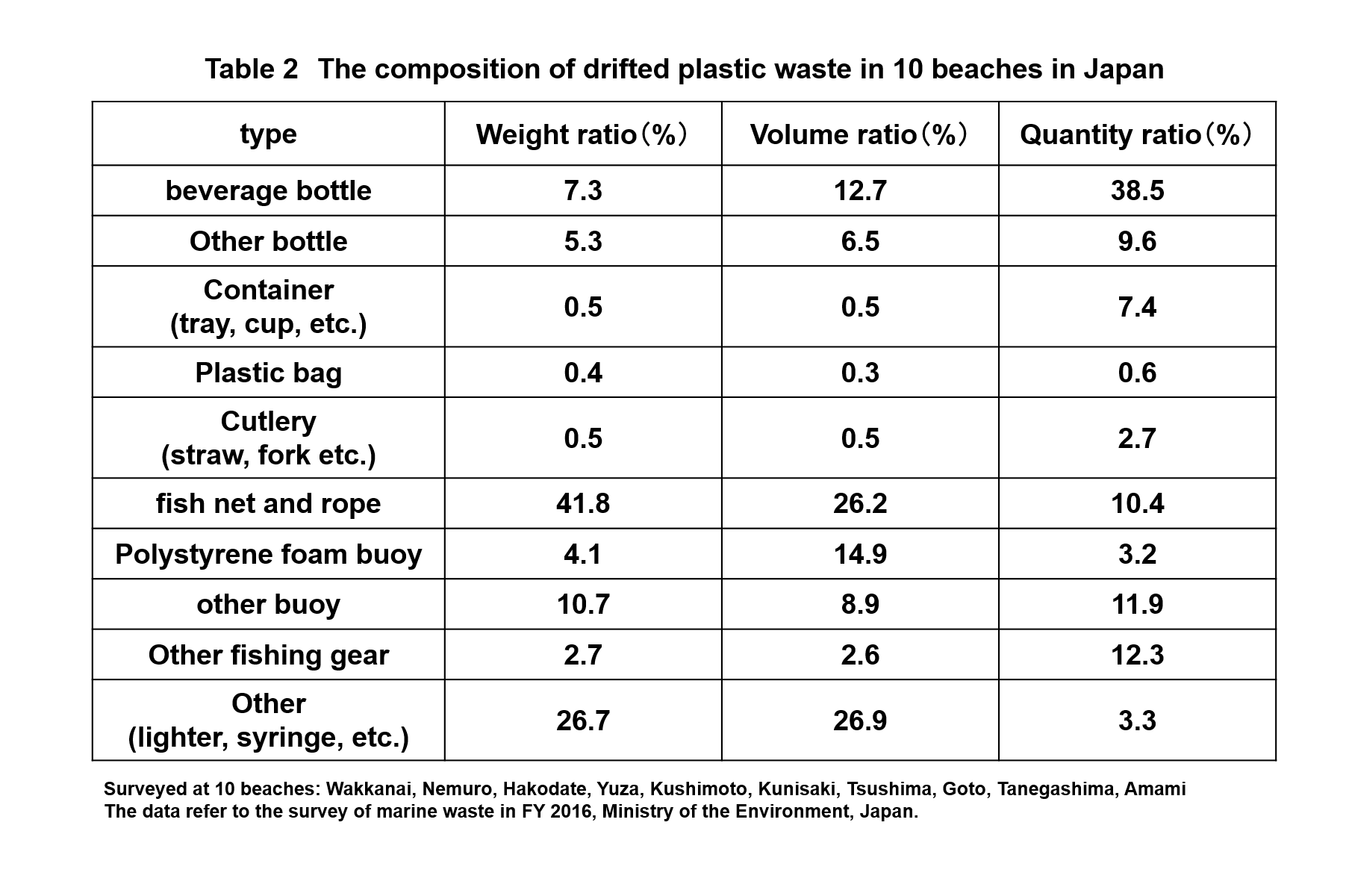

Ocean waste is categorized into three: drifted, drifting, and sea bottom litter. Drifted wood or seaweed can be seen in the morning even in well-maintained beaches. The composition of drifted plastic waste in 10 beaches in Japan is shown in Table 2. Data in Table 2 refer to the results of a survey of marine litter in FY 2016. This survey contained drifted litter from overseas, but most of them came from daily life and fishery. Straws or muddlers are used in cafés and family restaurants in Japan, but they are managed as industrial waste by each company. Ideally, no waste should exist except illegal littering and plastic in Table 2, which should belong to take-out products. Most drifted litter are lighter than water; thus, plastic waste has a high composition percentage. Industrial domestic waste in Figure 2 shows that thinking that only plastic litter is discharged into the environment is difficult, and the existence of many other kinds of litter we could not realize yet cannot be denied.

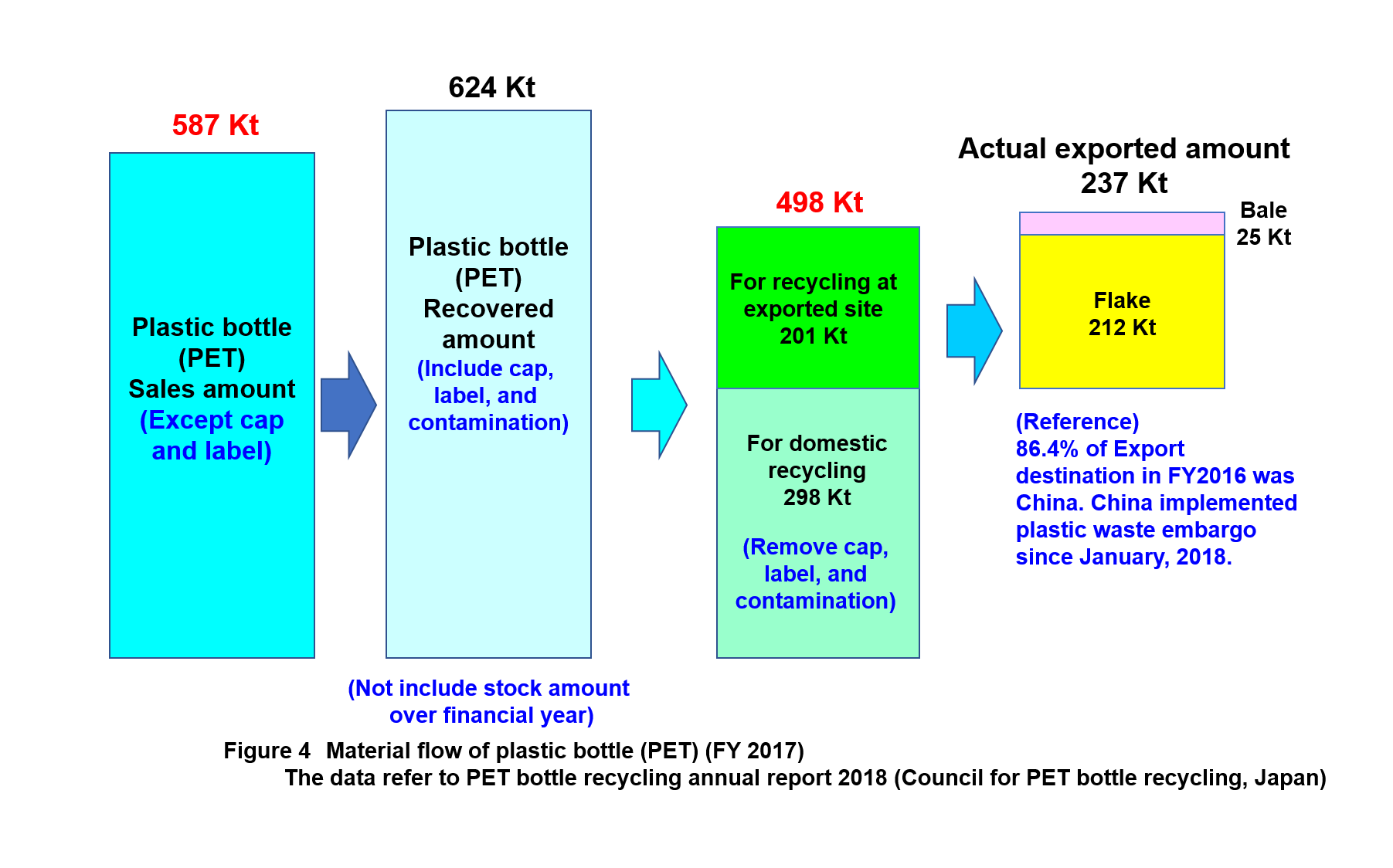

Figure 4 shows the material flow of plastic bottle made by polyethylene terephthalate (PET) for beverage, which is the highest percentage of drifted plastic litter except fishery waste. The Council for PET Bottle Recycling summarized the details on their web site (http://www.petbottle-rec.gr.jp/english/). According to their public annual report in 2018, the sales amount of plastic bottle was 587 thousand tons in FY 2017. Cups and labels were not included. Recovered plastic bottles totaled 62.4 thousand tons, which exceeded the sales amount because they included cups, labels, and leftovers when they were recovered. In addition, that quantity did not include stock over financial years. After washing the bottles, the amount of PET was 498 thousand tons, and all were used for material or thermal recycling. Domestic recycled product in FY 2017 was composed of plastic bottle, sheet, fiber, and others, and accounted for 25.2%, 47.2%, 25.4%, and 2.2%, respectively. The recycle ratio calculated with sales amount was 84.8%. This amount is higher than about 40% of the EU and 20% of the USA. Figure 4 shows that the material flow of recovered waste is apparently managed well. Therefore, a part of 89 thousand tons of the differences between plastic bottle sales amount and material recycle amount would be discharged into not only oceans but also rivers, mountains, and parks.

Table 2 shows that plastic waste from home such as plastic bottle is called disposable, single-use, or one-way plastics. Education is necessary for that litter to be thrown into the garbage bin. The material flow in Figure 4 shows that few plastic bottles would be discharged into oceans or mountains if waste is thrown correctly. However, plastic litter discharged into the environment will be compiled. Therefore, the only solution would be banning the daily use disposable plastics if littering cannot be managed, as discussed in Europe

4.Waste plastic embargo

China implemented a waste plastic embargo since January, 2018, and waste plastics have nowhere to go in the world. This situation occurred because numerous companies in several countries export inferior products, and they do not improve. According to the material flow of plastic bottle in Figure 4, the amount of material for recycling is 498 thousand tons, which is divided into overseas recycling and domestic recycling. Overseas recycling amounted to 201 thousand tons (approximately 40%), and domestic recycling was 298 thousand tons (approximately 60%). In the previous year (FY 2016), 86.4% of plastic bottles was exported to China, and 90% of plastic bottles was exported as flake state to foreign countries (nine-digit statistical code: 31590110). The plastic bottle flake has a size of 8 mm * 8 mm and is washed after crushing. The grade can process plastic products. Globalization has been helping build factories in developing countries such as Chana. Even if the raw material is produced in Japan, the products are not necessarily manufactured in Japan. The material flow of plastics in Figure 3 shows that products were exported from Japan to foreign counties were for material recycle grade and not for chemical recycling, thermal recycling, or non-utilized grade.

5.Effort and agenda for Sound Material-Cycle Society

The situation of building the Sound Material-Cycle Society in Japan is explained in this article. Differences are noted between that in Japan and those in other countries because of social system, lifestyle, and nationality. Although Japan could manage the litter with material flow to form a Sound Material-Cycle Society, some waste goes out from circulation and is discharged into the environment. This problem must be solved.

Based on The Basic Act of Sound Material-Cycle Society, the basic plan which is set up every five years becomes fourth term. The fourth version of The Basic Act of Sound Material-Cycle Society approved by the cabinet in May, 2018 reflected the basic concept of sustainable development goals and stated integrative action to achieve an environmentally, economically, and socially sustainable society. In addition, it set up the concrete numerical goal and enforcement of policy to be conducted by the government by 2025. It also indicated building the processing system of disaster waste. About 20 years have passed since The Basic Act of Sound Material-cycle Society was set up. The effort was gradually reflected in statistical data because laws were established, and each industry conducted actions and educational campaign.

However, society will be changing. Many people understand what society we should aim for, but at the same time, people want a good life and buy things for their satisfaction. New things are developed every day. Using plastic is necessary for individual packaging and weight saving to develop and install self-register systems at convenience stores or delivery by drone. The drone itself is made of plastic. Plastic waste will increase, and the amount of litter discharged into the environment will rise if we cannot change the ratio of littering and illegal dumping. Therefore, social system and lifestyle should be discussed.

The Meiji University Polymer Science Center will conduct a study group to discuss plastic waste, which makes our life better and connects to environmental destruction once discharged into the environment. The results will be published for enlightenment.

May 13, 2020 – Hitoshi Sugiyama, translator

This is a translation from the Japanese original article written by Kazukiyo Nagai, which was published on June 3, 2019.